Unimog

Operating Instructions

Symbols

G WARNING

Warning notes make you aware of dangers which could pose a threat to your health or life, or to the health and life of others.

HEnvironmental note

Environmental notes provide you with information on environmentally aware actions or disposal.

! Notes on material damage alert you to dangers that could lead to damage to your vehicle.

i These symbols indicate useful instructions or further information that could be helpful to you.

XThis symbol designates an instruction you must follow.

XSeveral consecutive symbols indicate an instruction with several steps.

(Ypage) This symbol tells you where you can find further information on a topic.

YY This symbol indicates a warning or an instruction that is continued on the next page.

Display This text indicates a message on the display.

Welcome to the world of Mercedes-Benz

Before you first drive off, read these Operating Instructions carefully and familiarise yourself with your vehicle. Please adhere to the information and warning notes in these Operating Instructions for your own safety and to ensure a longer operating duration of the vehicle. Failure to observe the instructions may lead to damage to the vehicle or personal injury.

The equipment or model designation of your vehicle may differ according to:

Rmodel

Rorder

Rcountry specification Ravailability

The illustrations in this manual show a left- hand-drive vehicle. The location of vehicle parts and controls for right-hand drive vehicles differ accordingly.

Mercedes-Benz is constantly updating its vehicles to the state of the art.

Mercedes-Benz therefore reserves the right to introduce changes in:

Rdesign Requipment Rtechnical features

Therefore, the descriptions provided may occasionally differ from your own vehicle.

The following are components of the vehicle: ROperating Instructions

RMaintenance or Service Booklet REquipment-dependent supplements

Always keep these documents in the vehicle. If you sell the vehicle, always pass the documents on to the new owner.

i You can get to know some of the important features of your vehicle in German and English in the interactive Operating Instructions on the Internet at:

www.mercedes-benz.de/ betriebsanleitung-unimog

You can also use the Mercedes-Benz Guide smartphone app:

Apple® iOS

Android™

Please note that the Mercedes-Benz Guide app may not yet be available in your country.

The technical documentation team at Daimler AG wishes you safe and pleasant motoring.

4055840516 É4055840516_ËÍ

Contents 3

|

Index ………………………………………………. |

4 |

|

Introduction ………………………………….. |

27 |

|

At a glance ……………………………………. |

35 |

|

Safety …………………………………………… |

47 |

|

Opening and closing ……………………… |

55 |

|

Driver’s workstation ……………………… |

63 |

|

Climate control ……………………………… |

97 |

|

On-board computer and displays …. |

109 |

|

Audio systems ……………………………. |

147 |

|

Driving mode ………………………………. |

157 |

|

Hydraulic system ………………………… |

227 |

|

Working mode …………………………….. |

261 |

|

Maintenance and care …………………. |

285 |

|

Breakdown assistance ………………… |

311 |

|

Wheels and tyres ………………………… |

337 |

|

Technical data …………………………….. |

355 |

4Index

1, 2, 3 …

|

24 V socket |

92 |

|

Centre console ………………………….. |

|

|

A |

|

|

ABS (Anti-lock Braking System) |

165 |

|

ABS Off-road program ……………….. |

|

|

Braking with anti-lock protection … |

165 |

|

Important safety notes ……………… |

164 |

|

ABS off-road program |

|

|

Activating/deactivating …………….. |

165 |

|

Access steps |

|

|

Cleaning ………………………………….. |

288 |

|

Important safety notes ……………… |

288 |

|

Tailgate …………………………………… |

276 |

|

Active charcoal filter |

|

|

Cleaning ………………………………….. |

303 |

|

AdBlue® |

|

|

Additive ………………………………….. |

366 |

|

Consumption …………………………… |

215 |

|

Disposal ………………………………….. |

366 |

|

Gauge …………………………………….. |

111 |

|

General notes ………………………….. |

365 |

|

High outside temperatures ………… |

366 |

|

Important safety notes ……………… |

218 |

|

Low outside temperatures …………. |

366 |

|

Purity ……………………………………… |

366 |

|

Refuelling ………………………………… |

218 |

|

Service product ……………………….. |

365 |

|

Storage …………………………………… |

366 |

|

Tank ……………………………………….. |

218 |

|

AdBlue® empty (display message) |

|

|

Yellow event window ………………… |

131 |

|

AdBlue® reserve (display mes- |

|

|

sage) |

|

|

Yellow event window ………………… |

131 |

|

AdBlue® very low (display mes- |

|

|

sage) |

|

|

Yellow event window ………………… |

131 |

|

Additional mirror |

|

|

Vehicles with mowing door ………….. |

72 |

|

Additional turn signal |

|

|

Replacing bulbs …………………………. |

83 |

|

Adjusting |

|

|

Auxiliary headlamps ……………………. |

78 |

|

Adjusting the headlamp range ……….. |

75 |

|

Adjusting the volume |

|

|

Audio equipment ……………………… |

122 |

|

Radio ……………………………………… |

122 |

|

Air conditioning |

|

|

General notes ……………………………. |

98 |

|

Air-conditioning system |

|

|

Climate control ………………………….. |

99 |

|

Switching on/off ……………………… |

101 |

|

Air-recirculation mode |

|

|

Activating/deactivating …………….. |

100 |

|

Airflow |

|

|

Setting ……………………………………. |

100 |

|

Alarm |

|

|

Operating (on-board computer) ….. |

120 |

|

Attachments/add-on equipment ……. |

31 |

|

Audio equipment |

|

|

Adjusting the volume (steering |

|

|

wheel buttons) …………………………. |

122 |

|

Operating (on-board computer) ….. |

122 |

|

Audio system |

|

|

Bluetooth® settings ………………….. |

153 |

|

General notes ………………………….. |

148 |

|

Important safety notes ……………… |

148 |

|

Operating system (overview) ……… |

150 |

|

Automatic car wash …………………….. |

289 |

|

Automatic gearshift |

|

|

see Telligent automatic gearshift |

|

|

Auxiliary consumers ……………………. |

327 |

|

Auxiliary headlamp |

|

|

Turn signal lamp ………………………… |

83 |

|

Auxiliary headlamps |

|

|

General notes ……………………………. |

77 |

|

Lighting system …………………………. |

77 |

|

Replacing bulbs …………………………. |

83 |

|

Auxiliary heating |

|

|

Air distribution and temperature …. |

105 |

|

Engine preheating …………………….. |

106 |

|

Fuels ………………………………………. |

102 |

|

Immediate heating mode …………… |

104 |

|

Important safety notes ……………… |

102 |

|

Mandatory switch-off ………………… |

103 |

|

Preselected heating mode …………. |

105 |

|

Problem (fault) …………………………. |

107 |

|

Timer ……………………………………… |

104 |

|

Auxiliary heating system |

|

|

Alarm function …………………………. |

106 |

|

Axle loads |

|

|

Vehicle identification plate ………… |

356 |

|

Axle reduction ratio |

|

|

Vehicle identification plate ………… |

356 |

|

B |

|

|

Ballast weights |

|

|

Weights …………………………………… |

262 |

|

Batteries |

|

|

Care ……………………………………….. |

309 |

|

Charging …………………………………. |

309 |

|

Checking the fluid level …………….. |

308 |

|

Disconnecting and connecting ……. |

308 |

|

Disconnecting/connecting the |

|

|

battery cover …………………………… |

307 |

|

Important safety notes ……………… |

306 |

|

Maintenance ……………………………. |

306 |

|

Battery cover |

|

|

Disconnecting/connecting ………… |

307 |

|

Battery isolator switch |

|

|

Interrupting the voltage supply …….. |

91 |

|

Re-establishing a voltage supply …… |

91 |

|

Voltage supply …………………………… |

90 |

|

Before pulling away |

|

|

Checking the supply pressure in |

|

|

the compressed-air brake system .. |

161 |

|

Important safety notes ……………… |

159 |

|

Bleeding the fuel system |

|

|

With prefilter ……………………………. |

322 |

|

Without prefilter ……………………….. |

322 |

|

BlueTec® exhaust gas aftertreat- |

|

|

ment |

|

|

AdBlue® service product ……………. |

365 |

|

Notes ……………………………………….. |

30 |

|

Status indicator ……………………….. |

114 |

|

Bluetooth® |

|

|

Activating/deactivating …………….. |

154 |

|

Connection requirements ………….. |

154 |

|

Notes ……………………………………… |

153 |

|

Pairing a mobile phone ……………… |

154 |

|

Settings ………………………………….. |

153 |

|

Body |

|

|

Cleaning ………………………………….. |

287 |

|

Bottle holder |

|

|

Important safety notes ……………….. |

93 |

|

Index |

5 |

|

|

Brake fluid |

||

|

Hydraulic clutch mechanism sys- |

||

|

tem ………………………………………… |

361 |

|

|

Notes ……………………………………… |

361 |

|

|

Brake lamp |

||

|

Replacing bulbs …………………………. |

85 |

|

|

Brake supply pressure in circuit 1 |

||

|

too low (display message) |

||

|

Red event window ……………………. |

139 |

|

|

Brake system |

||

|

Checking for leaks ……………………. |

163 |

|

|

Service brake …………………………… |

163 |

|

|

Brakes |

||

|

Checking for leaks in the |

||

|

compressed-air brake system …….. |

163 |

|

|

Display message in the red event |

||

|

window …………………………………… |

142 |

|

|

Brakes, axle 1 Maintenance due |

||

|

immediately (display message) |

||

|

Yellow event window ………………… |

134 |

|

|

Braking |

||

|

ABS ………………………………………… |

164 |

|

|

Anti-lock protection ………………….. |

165 |

|

|

Continuous brake …………………….. |

167 |

|

|

Engine brake ……………………………. |

167 |

|

|

Four-wheel parking brake ………….. |

166 |

|

|

Parking brake ………………………….. |

166 |

|

|

Releasing the spring-loaded park- |

||

|

ing brake cylinders …………………… |

335 |

|

|

Breakdown assistance |

||

|

Bleeding the fuel system ……………. |

322 |

|

|

Cab safety prop ……………………….. |

312 |

|

|

Charging the compressed-air sys- |

||

|

tem from an outside source ……….. |

330 |

|

|

Chock …………………………………….. |

314 |

|

|

Compressed-air pistol with |

||

|

compressed-air hose ………………… |

312 |

|

|

Draining the fuel prefilter …………… |

321 |

|

|

Fire extinguisher ………………………. |

312 |

|

|

First-aid kit ……………………………… |

312 |

|

|

Fuses ……………………………………… |

327 |

|

|

Important safety notes ……………… |

312 |

|

|

Jack ……………………………………….. |

312 |

|

|

Jump-starting …………………………… |

331 |

|

|

Pump lever, storing …………………… |

312 |

|

|

Releasing the spring-loaded park- |

||

|

ing brake cylinders …………………… |

335 |

|

|

Renewing the fuel filter ……………… |

320 |

6Index

|

Replacing the fuel prefilter …………. |

319 |

|

Square spanner ……………………….. |

312 |

|

Starting and stopping the engine |

|

|

with the cab tilted …………………….. |

318 |

|

Tilting the cab ………………………….. |

314 |

|

Tool bag ………………………………….. |

312 |

|

Towing and tow-starting ……………. |

333 |

|

Tyre inflator hose ……………………… |

312 |

|

Warning lamp …………………………… |

312 |

|

Warning triangle ………………………. |

312 |

|

Wheel wrench ………………………….. |

312 |

|

Window cleaner/scraper …………… |

313 |

|

Buttons |

|

|

see On-board computer |

|

|

C |

|

|

Cab |

|

|

Cable ducts ……………………………….. |

95 |

|

Notes on tilting ………………………… |

314 |

|

Problems in tilting the cab …………. |

318 |

|

Tilting ……………………………………… |

314 |

|

Tilting back ……………………………… |

316 |

|

Tilting forwards ………………………… |

315 |

|

Tilting unit ……………………………….. |

314 |

|

Cab safety prop |

|

|

Vehicle tool kit …………………………. |

312 |

|

Cab tilting pump |

|

|

Pump lever ………………………………. |

313 |

|

Cable ducts |

|

|

Cab ………………………………………….. |

95 |

|

Cables and compressed-air lines |

|

|

Trailer …………………………………….. |

220 |

|

Camera |

|

|

Driving systems ……………………….. |

196 |

|

Important safety notes ……………… |

196 |

|

Capacities (technical data) …………… |

367 |

|

Care |

|

|

see Cleaning and care |

|

|

CD radio |

|

|

Anti-theft protection …………………. |

148 |

|

Bluetooth® settings ………………….. |

153 |

|

Function overview …………………….. |

153 |

|

Operating system (overview) ……… |

150 |

|

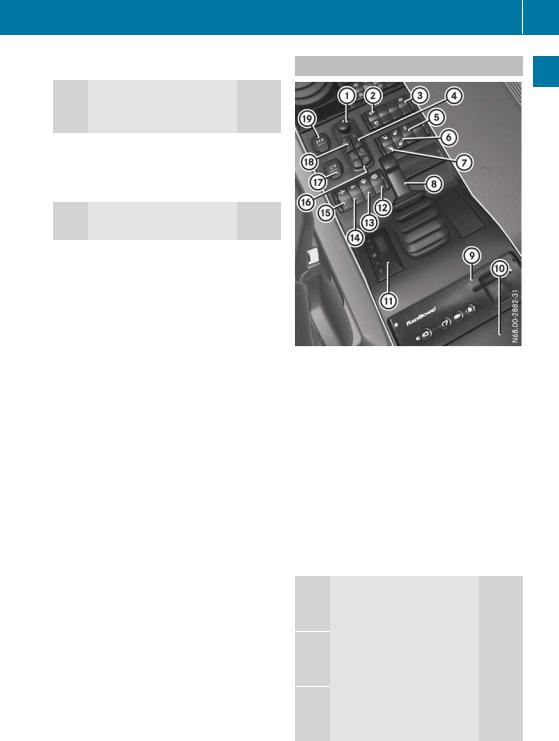

Centre console |

|

|

Front ………………………………………… |

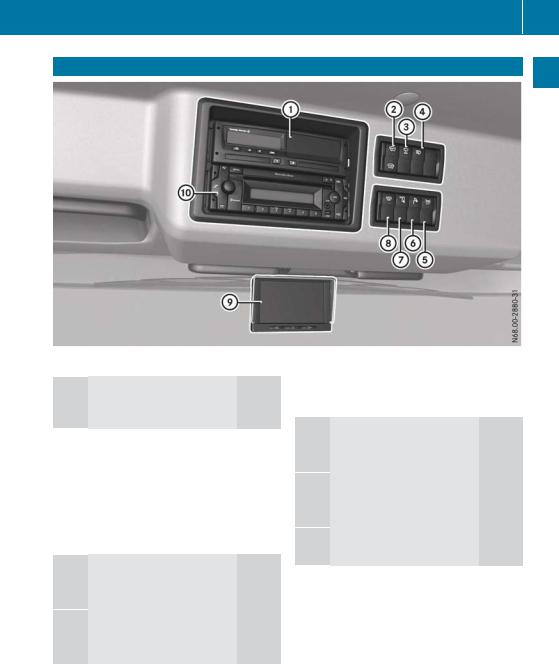

40 |

|

Rear …………………………………………. |

41 |

|

Switch panel overview ………………… |

40 |

|

Changing a bulb |

|

|

Front foglamps …………………………… |

83 |

|

Overview of bulbs ………………………. |

81 |

|

Rotating beacon …………………………. |

86 |

|

Side-mounted turn signal lamps …… |

84 |

|

Strobe light ……………………………….. |

87 |

|

Working-area lamp ……………………… |

86 |

|

Changing a wheel |

|

|

Fitting a wheel …………………………. |

325 |

|

Important safety notes ……………… |

323 |

|

Positioning a jack …………………….. |

324 |

|

Removing a wheel …………………….. |

324 |

|

Retightening wheel nuts ……………. |

326 |

|

Tyre inflator connection …………….. |

326 |

|

Changing bulbs |

|

|

Licence plate lighting ………………….. |

85 |

|

Notes ……………………………………….. |

79 |

|

Perimeter lamp ………………………….. |

85 |

|

Chassis |

|

|

Cleaning ………………………………….. |

287 |

|

Chassis protection |

|

|

Cleaning and care …………………….. |

290 |

|

Check tyre pressure (display mes- |

|

|

sage) |

|

|

Red event window ……………………. |

143 |

|

Checking the anti-corrosion pro- |

|

|

tection ………………………………………… |

305 |

|

Child |

|

|

Restraint system ………………………… |

52 |

|

Cleaning |

|

|

Active charcoal filter …………………. |

303 |

|

Fine particle filter ……………………… |

303 |

|

Cleaning and care |

|

|

Access steps …………………………… |

288 |

|

After driving off-road or on a con- |

|

|

struction site …………………………… |

290 |

|

Automatic car wash ………………….. |

289 |

|

Chassis and body ……………………… |

287 |

|

Chassis and underbody protec- |

|

|

tion ………………………………………… |

290 |

|

cleaning seat covers …………………. |

286 |

|

Cleaning the exterior ………………… |

286 |

|

Cleaning the interior …………………. |

286 |

|

Engine cleaning ……………………….. |

289 |

|

High-pressure cleaning ……………… |

288 |

|

Light-alloy wheels …………………….. |

289 |

|

Notes on care ………………………….. |

286 |

|

Seat belts ……………………………….. |

286 |

|

Cleaning the air filter |

|

|

Maintenance ……………………………. |

304 |

|

Cleaning the interior |

|

|

Cleaning and care …………………….. |

286 |

|

Cleaning the radiator |

|

|

Air conditioning condenser ………… |

301 |

|

Charge-air cooler ……………………… |

302 |

|

Engine radiator ………………………… |

301 |

|

Hydraulic oil cooling fan ……………. |

302 |

|

Hydrostatic drive system oil |

|

|

cooler …………………………………….. |

303 |

|

Important safety notes ……………… |

301 |

|

Power hydraulics oil cooler ………… |

302 |

|

Radiator quick cleaning system ….. |

191 |

|

Torque converter clutch oil cooler .. |

303 |

|

Working hydraulics oil cooler ……… |

303 |

|

Cleaning the release valve on the |

|

|

air intake duct |

|

|

Maintenance ……………………………. |

304 |

|

Cleaning the vehicle exterior |

|

|

Cleaning and care …………………….. |

286 |

|

Important safety notes ……………… |

286 |

|

Climate control |

|

|

Air conditioning ……………………….. |

101 |

|

Auxiliary heater ………………………… |

102 |

|

Cooling …………………………………… |

101 |

|

Dehumidifying ………………………….. |

101 |

|

Demisting the windscreen …………. |

101 |

|

Function control panel ………………… |

99 |

|

Mixed air operation …………………… |

100 |

|

Overview …………………………………… |

99 |

|

Residual heat …………………………… |

101 |

|

Setting the air distribution …………. |

100 |

|

Setting the air vents …………………. |

101 |

|

Setting the airflow ……………………. |

100 |

|

Setting the temperature ……………. |

100 |

|

Switching air-recirculation mode |

|

|

on/off …………………………………….. |

100 |

|

Switching windscreen heating |

|

|

on/off ………………………………………. |

90 |

|

Clutch |

|

|

Faulty, Visit workshop (display |

|

|

message in the yellow event win- |

|

|

dow) ……………………………………….. |

136 |

|

Heavily loaded (display message |

|

|

in the grey event window) ………….. |

130 |

|

Heavily loaded (display message |

|

|

in the yellow event window) ……….. |

136 |

Index 7

Clutch actuation system

see Hydraulic clutch actuation system

Clutch faulty (display message)

|

Red event window ……………………. |

141 |

|

Clutch pedal |

|

|

Folding out (display message, |

|

|

grey event window) …………………… |

130 |

|

Clutch/transmission circuit |

|

|

Checking the supply pressure …….. |

161 |

|

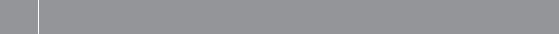

Cockpit |

|

|

Overview …………………………………… |

36 |

|

Switch panel overview ………………… |

40 |

|

Cold climate package |

|

|

Before cold-starting ………………….. |

224 |

|

Cold-resistant service products ….. |

224 |

|

Cold-start limits ……………………….. |

224 |

|

Coolant preheating …………………… |

224 |

|

Engine does not start ………………… |

225 |

|

General notes ………………………….. |

224 |

|

Starting the engine …………………… |

225 |

|

Winter driving ………………………….. |

224 |

|

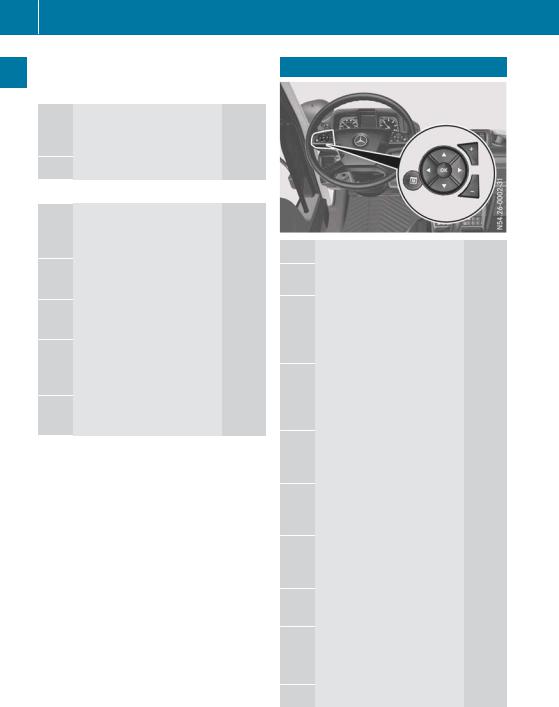

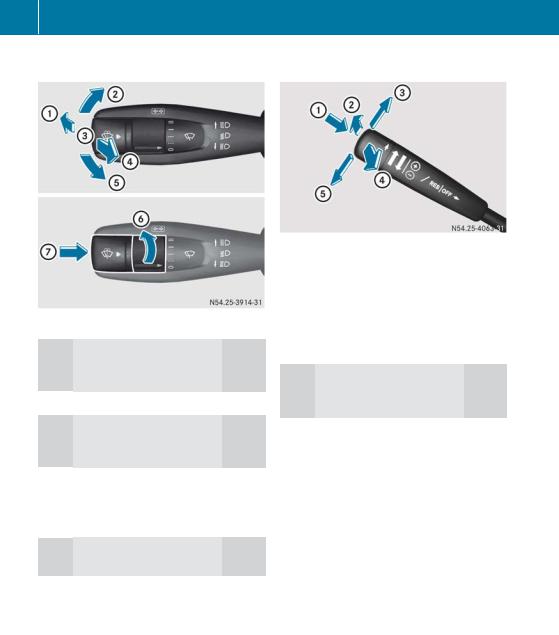

Combination switch |

|

|

Lighting system …………………………. |

75 |

|

Overview …………………………………… |

44 |

|

Compressed-air brake system |

|

|

Checking the reservoir pressure …. |

161 |

|

Draining ………………………………….. |

304 |

|

Compressed-air connection |

|

|

Cab ………………………………………….. |

94 |

|

Compressed-air lines and cables |

|

|

Trailer …………………………………….. |

220 |

|

Compressed-air pistol with |

|

|

compressed-air hose |

|

|

Vehicle tool kit …………………………. |

312 |

|

Compressed-air reservoir |

|

|

Draining ………………………………….. |

304 |

|

Identification plate ……………………. |

380 |

|

Technical data …………………………. |

379 |

|

Compressed-air reservoir circuit 1 |

|

|

Draining ………………………………….. |

304 |

|

Compressed-air reservoir circuit 2 |

|

|

Draining ………………………………….. |

304 |

|

Compressed-air reservoir for aux- |

|

|

iliary consumers |

|

|

Draining ………………………………….. |

304 |

|

Compressed-air reservoir for tyre |

|

|

pressure control system |

|

|

Draining ………………………………….. |

304 |

8Index

|

Compressed-air reservoir regener- |

|

|

ation |

|

|

Draining ………………………………….. |

304 |

|

Compressed-air system |

|

|

Charging from an outside source … |

330 |

|

Display message in the yellow |

|

|

event window …………………………… |

135 |

|

Condensation in compressed-air |

|

|

reservoir (display message) |

|

|

Yellow event window ………………… |

135 |

|

Constant working speed |

|

|

Engine speed setting ………………… |

263 |

|

Constant working speed mode |

|

|

Activating/deactivating using the |

|

|

control lever and with the blue |

|

|

button …………………………………….. |

264 |

|

Activating/deactivating using the |

|

|

control lever without the blue but- |

|

|

ton …………………………………………. |

264 |

|

Activating/deactivating with the |

|

|

buttons on the steering wheel ……. |

263 |

|

Consumption |

|

|

AdBlue® ………………………………….. |

215 |

|

Fuel ………………………………………… |

215 |

|

Oil (engine) ……………………………… |

215 |

|

Continuous brake |

|

|

Activating/deactivating …………….. |

168 |

|

Important safety notes ……………… |

167 |

|

Continuous consumers |

|

|

Working hydraulics circuit I ………… |

252 |

|

Control lever |

|

|

Changing the installation position …. |

95 |

|

Conversions/equipment ……………….. |

31 |

|

Coolant |

|

|

Additive with antifreeze protec- |

|

|

tion ………………………………………… |

362 |

|

Additive without antifreeze pro- |

|

|

tection ……………………………………. |

362 |

|

Checking coolant level and top- |

|

|

ping up ……………………………………. |

293 |

|

Service product ……………………….. |

362 |

|

Coolant level too low (display mes- |

|

|

sage) |

|

|

Red event window ……………………. |

140 |

|

Coolant temperature |

|

|

Checking (on-board computer) …… |

125 |

|

Coolant temperature too high (dis- |

|

|

play message) |

|

|

Yellow event window ………………… |

135 |

|

Crawler gears |

|

|

With Telligent® automatic gear- |

|

|

shift ……………………………………….. |

184 |

|

With Telligent® gearshift ……………. |

184 |

|

Cruise control |

|

|

Activating ………………………………… |

194 |

|

Activating while driving ……………… |

194 |

|

Activation conditions ………………… |

194 |

|

Adjusting the speed tolerance ……. |

195 |

|

Deactivating …………………………….. |

196 |

|

Driving ……………………………………. |

195 |

|

Driving tips ……………………………… |

195 |

|

Important safety notes ……………… |

193 |

|

Overtaking ………………………………. |

196 |

|

Overview …………………………………. |

194 |

|

Selecting …………………………………. |

194 |

|

Setting a speed ………………………… |

195 |

|

Setting the speed and the speed |

|

|

tolerance ………………………………… |

195 |

|

Cruise control lever |

|

|

Hydrostatic drive system …………… |

205 |

|

Overview …………………………………… |

44 |

|

Telligent automatic gearshift ……… |

175 |

|

Telligent gearshift …………………….. |

169 |

|

Cumulation |

|

|

Working hydraulics circuit II, vehi- |

|

|

cles with gear pump …………………. |

255 |

|

Cup holder |

|

|

Important safety notes ……………….. |

93 |

|

D |

|

|

Data plate |

|

|

Engine …………………………………….. |

356 |

|

Daylight driving lamps |

|

|

Switching on/off ………………………… |

74 |

|

Declarations of conformity …………….. |

29 |

|

Device camera |

|

|

Connecting ……………………………… |

197 |

|

Driving systems ……………………….. |

196 |

|

General notes ………………………….. |

197 |

|

Switching on/off ……………………… |

198 |

|

Diagnostic data |

|

|

Calling up (on-board computer) ….. |

125 |

|

Diagnostics connection |

|

|

Operating safety and vehicle |

|

|

approval ……………………………………. |

29 |

|

Diesel |

|

|

Refuelling ………………………………… |

216 |

|

Diesel fuels |

|

|

Fuel additives ………………………….. |

365 |

|

Important safety notes ……………… |

364 |

|

Low outside temperatures …………. |

365 |

|

Setting the fuel grade (sulphur |

|

|

content) in the on-board com- |

|

|

puter ………………………………………. |

364 |

|

Diesel particle filter |

|

|

Automatic regeneration …………….. |

213 |

|

Blocking regeneration ……………….. |

214 |

|

Filter replacement ……………………. |

215 |

|

Full, Stop vehicle, Consult service |

|

|

centre (display message in the red |

|

|

event window) …………………………. |

139 |

|

Important safety notes ……………… |

213 |

|

Manual regeneration not possible |

|

|

(display message, grey event win- |

|

|

dow) ……………………………………….. |

129 |

|

Regeneration disabled (display |

|

|

message in the grey event win- |

|

|

dow) ……………………………………….. |

129 |

|

Starting manual regeneration …….. |

214 |

|

Diesel particle filter full, engine |

|

|

performance is reduced (display |

|

|

message) |

|

|

Yellow event window ………………… |

131 |

|

Diesel particle filter saturated (dis- |

|

|

play message) |

|

|

Yellow event window ………………… |

131 |

|

Diesel particle filter saturation |

|

|

level increased (display message) |

|

|

Yellow event window ………………… |

131 |

|

Diesel reserve (display message) |

|

|

Yellow event window ………………… |

134 |

|

Differential lock |

|

|

Engaging …………………………………. |

190 |

|

Important safety notes ……………… |

190 |

|

Differential locks |

|

|

Disengaging …………………………….. |

190 |

|

Diodes |

|

|

Layout …………………………………….. |

328 |

|

Dipped-beam headlamps |

|

|

Replacing bulbs …………………………. |

82 |

|

Index |

9 |

|

|

Setting for driving abroad (sym- |

||

|

metrical) …………………………………… |

73 |

|

|

Switching on/off ………………………… |

74 |

|

|

Direction of travel preselection |

||

|

Telligent automatic gearshift with |

||

|

cruise control lever …………………… |

176 |

|

|

Telligent gearshift with cruise con- |

||

|

trol lever …………………………………. |

170 |

|

|

Telligent® automatic gearshift |

||

|

with operating lever ………………….. |

176 |

|

|

Telligent® gearshift with operat- |

||

|

ing lever ………………………………….. |

170 |

|

|

Display |

||

|

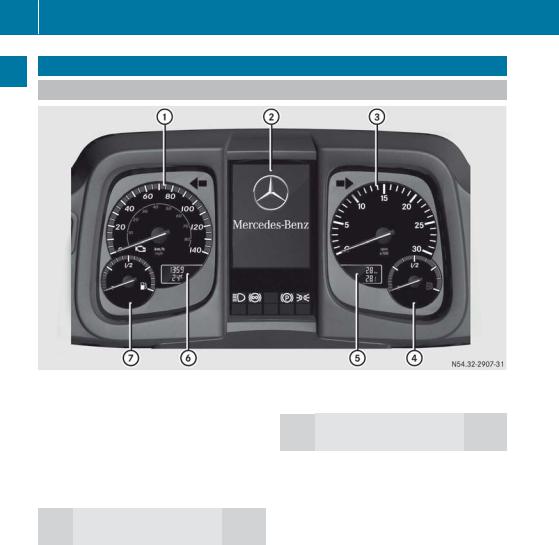

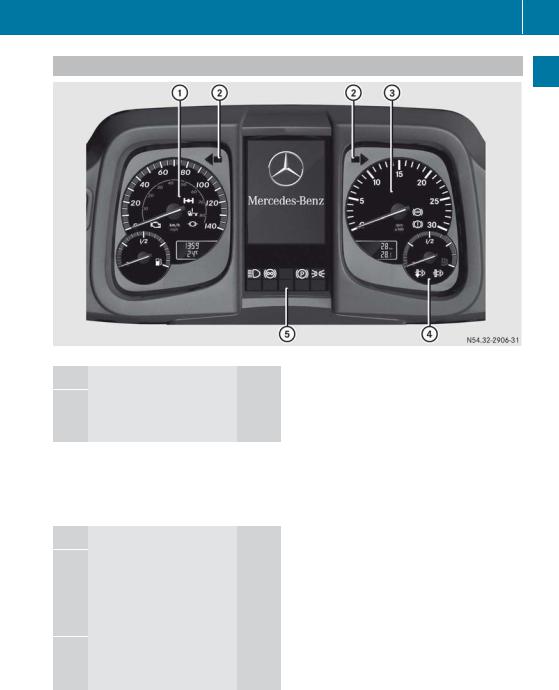

Instrument cluster ……………………… |

38 |

|

|

On-board computer ………………….. |

115 |

|

|

Outside temperature …………………. |

112 |

|

|

Setting the language (on-board |

||

|

computer) ……………………………….. |

127 |

|

|

Time ……………………………………….. |

112 |

|

|

Total distance recorder ……………… |

112 |

|

|

Trip meter ……………………………….. |

112 |

|

|

Display and instrument cluster |

||

|

controls malfunction (display mes- |

||

|

sage) |

||

|

Yellow event window ………………… |

137 |

|

|

Display messages |

||

|

see Grey event window |

||

|

see Red event window |

||

|

see Yellow event window |

||

|

Distance recorder |

||

|

Total distance recorder ……………… |

112 |

|

|

Doors |

||

|

Access steps (entering and exit- |

||

|

ing) ………………………………………….. |

60 |

|

|

Entering and exiting ……………………. |

60 |

|

|

Grab handles (entering and exit- |

||

|

ing) ………………………………………….. |

60 |

|

|

Mowing door, important safety |

||

|

notes ……………………………………….. |

57 |

|

|

Normal door, important safety |

||

|

notes ……………………………………….. |

56 |

|

|

Draining |

||

|

Compressed-air reservoir circuit |

||

|

1 ……………………………………………. |

304 |

|

|

Compressed-air reservoir circuit |

||

|

2 ……………………………………………. |

304 |

|

|

Compressed-air reservoir for aux- |

||

|

iliary consumers ………………………. |

304 |

10 Index

|

Compressed-air reservoir for tyre |

|

|

pressure control system ……………. |

304 |

|

Compressed-air reservoir regen- |

|

|

eration ……………………………………. |

304 |

|

Fuel prefilter ……………………………. |

321 |

|

Drive control faulty (display mes- |

|

|

sage) |

|

|

Yellow event window ………………… |

135 |

|

Driving abroad |

|

|

Lighting system …………………………. |

73 |

|

Symmetrical dipped beam …………… |

73 |

|

Driving and braking characteris- |

|

|

tics |

|

|

Changed (display message in the |

|

|

red event window) ……………………. |

142 |

|

Driving mode |

|

|

Differential lock ……………………….. |

190 |

|

Radiator quick cleaning system ….. |

191 |

|

Torque converter clutch …………….. |

185 |

|

Tyre pressure control system …….. |

186 |

|

Driving off-road |

|

|

ABS off-road program ……………….. |

165 |

|

Important safety notes ……………… |

210 |

|

Rules for driving off-road …………… |

211 |

|

see Off-road driving |

|

|

Driving style |

|

|

see Fuel consumption |

|

|

Driving systems |

|

|

Camera …………………………………… |

196 |

|

Cruise control ………………………….. |

193 |

|

Device camera …………………………. |

196 |

|

Front camera …………………………… |

196 |

|

Hydrostatic drive system …………… |

198 |

|

Reversing camera …………………….. |

196 |

|

Speed limiter …………………………… |

191 |

|

Driving the vehicle |

|

|

Attached equipment …………………. |

209 |

|

Important safety notes ……………… |

209 |

|

Driving time |

|

|

Checking (on-board computer) …… |

119 |

|

Driving tips |

|

|

Diesel particle filter ………………….. |

213 |

|

Driving ……………………………………. |

209 |

|

Driving abroad …………………………… |

73 |

|

Driving with a high centre of grav- |

|

|

ity ………………………………………….. |

209 |

|

Off-road driving ………………………… |

210 |

|

Running-in ………………………………. |

208 |

|

Symmetrical dipped beam …………… |

73 |

|

Use of cable winches ………………… |

213 |

|

Warning buzzer ………………………… |

216 |

|

Dual-mode steering |

|

|

Changing steering position ………….. |

70 |

|

Important safety notes ……………….. |

70 |

|

Overview …………………………………… |

70 |

|

E |

|

|

Electromagnetic compatibility |

|

|

Declaration of conformity ……………. |

29 |

|

Electronic immobiliser |

|

|

Overview …………………………………… |

59 |

|

Emergency equipment …………………. |

312 |

|

Engine |

|

|

Changing the power output …………. |

30 |

|

Checking the operating hours (on- |

|

|

board computer) ………………………. |

125 |

|

Cleaning ………………………………….. |

289 |

|

Cold start ………………………………… |

224 |

|

Data plate ……………………………….. |

356 |

|

Diagnostics indicator lamp ………… |

113 |

|

Does not start ………………………….. |

323 |

|

Oil consumption ………………………. |

215 |

|

Operating safety ………………………… |

30 |

|

Rectifying faults ……………………….. |

323 |

|

Setting the oil grade (on-board |

|

|

computer) ……………………………….. |

127 |

|

Setting the oil viscosity (on-board |

|

|

computer) ……………………………….. |

127 |

|

Starting …………………………………… |

160 |

|

Starting and stopping with the cab |

|

|

tilted ………………………………………. |

318 |

|

Stopping …………………………………. |

162 |

|

Technical data …………………………. |

357 |

|

Engine brake ……………………………….. |

167 |

|

Engine data plate ………………………… |

356 |

|

Engine faulty (display message) |

|

|

Yellow event window ………………… |

135 |

|

Engine oil |

|

|

Checking the oil level ………………… |

297 |

|

Checking the oil level (on-board |

|

|

computer) ……………………………….. |

125 |

|

Consumption …………………………… |

215 |

|

Miscibility ……………………………….. |

362 |

|

Multi-grade engine oils ……………… |

361 |

|

Oil change ……………………………….. |

361 |

|

Quality ……………………………………. |

361 |

|

SAE classification …………………….. |

361 |

|

Scope of use ……………………………. |

361 |

|

Setting viscosity (on-board com- |

|

|

puter) ……………………………………… |

127 |

|

Single-grade engine oil ……………… |

361 |

|

Topping up ………………………………. |

297 |

|

Engine oil level |

|

|

Checking …………………………………. |

297 |

|

Engine oil pressure too low (dis- |

|

|

play message) |

|

|

Red event window ……………………. |

140 |

|

Engine power output reduced |

|

|

(BlueTec® exhaust gas aftertreat- |

|

|

ment) (display message) |

|

|

Yellow event window ………………… |

131 |

|

Engine preheating |

|

|

Switching on/off ……………………… |

106 |

|

Engine speed mode |

|

|

Automatic activation …………………. |

262 |

|

Equipment operation ………………… |

262 |

|

General notes ………………………….. |

262 |

|

Manually activating/deactivating .. |

262 |

|

Engine speed setting |

|

|

Constant working speed ……………. |

263 |

|

General notes ………………………….. |

263 |

|

Idling speed …………………………….. |

263 |

|

Engine-driven power take-off |

|

|

Constant working speed ……………. |

263 |

|

Power take-off …………………………. |

265 |

|

Entry lamp |

|

|

Replacing bulbs …………………………. |

86 |

|

Equipment driving mode |

|

|

Power take-offs ………………………… |

264 |

|

Equipment operation |

|

|

Engine speed mode ………………….. |

262 |

|

Front mounting plate ………………… |

268 |

|

Front PTO shaft ………………………… |

267 |

|

Transport of equipment …………….. |

269 |

|

Working on equipment ………………. |

272 |

|

Working with equipment ……………. |

270 |

|

Equipment socket |

|

|

on the vehicle exterior ………………… |

92 |

|

Events |

|

|

Display (on-board computer) ……… |

125 |

|

Exterior lighting control |

|

|

Bulb failure indicator …………………… |

77 |

|

Index 11 |

|

|

Exterior mirrors |

|

|

Adjusting ………………………………….. |

71 |

|

Adjusting the exterior mirrors |

|

|

when using dual-mode steering ……. |

72 |

|

Adjusting the mirror arm ……………… |

72 |

|

Heating …………………………………….. |

72 |

|

Important safety notes ……………….. |

71 |

|

External mirror |

|

|

Additional mirror, vehicles with |

|

|

mowing door ……………………………… |

72 |

|

F |

|

|

Fine particle filter |

|

|

Cleaning ………………………………….. |

303 |

|

Fire extinguisher |

|

|

Vehicle tool kit …………………………. |

312 |

|

First-aid kit |

|

|

Vehicle tool kit …………………………. |

312 |

|

Fitting equipment |

|

|

Important safety notes ……………… |

269 |

|

Notes on connecting/disconnect- |

|

|

ing equipment ………………………….. |

269 |

|

To the tipper platform ……………….. |

274 |

|

Float settings |

|

|

Activating/deactivating using the |

|

|

keypad ……………………………………. |

246 |

|

Activating/deactivating with the |

|

|

control lever ……………………………. |

247 |

|

Working hydraulics circuit I ………… |

246 |

|

Fluid level |

|

|

Battery ……………………………………. |

308 |

|

Coolant …………………………………… |

293 |

|

Foglamps |

|

|

Switching on/off ………………………… |

74 |

|

Fording ……………………………………….. |

212 |

|

Four-wheel parking brake |

|

|

Applying/releasing …………………… |

166 |

|

Front camera |

|

|

Driving systems ……………………….. |

196 |

|

general instructions ………………….. |

197 |

|

Front flap |

|

|

Closing ……………………………………. |

292 |

|

Opening ………………………………….. |

292 |

|

Opening/closing ………………………. |

291 |

|

Removing ………………………………… |

293 |

|

Removing/replacing …………………. |

292 |

|

Replacing ………………………………… |

293 |

12 Index

|

Square spanner ……………………….. |

312 |

|

Front foglamps |

|

|

Replacing bulbs …………………………. |

83 |

|

Front mounting plate |

|

|

Equipment operation ………………… |

268 |

|

Front PTO shaft |

|

|

Constant working speed ……………. |

263 |

|

Correct use ……………………………… |

267 |

|

Cover ……………………………………… |

268 |

|

Displaying the operating hours …… |

125 |

|

Engaging/disengaging ………………. |

268 |

|

Important safety notes ……………… |

267 |

|

Limiting the PTO shaft speed ……… |

268 |

|

Limiting working speed ……………… |

268 |

|

Maintenance ……………………………. |

299 |

|

Method of operation …………………. |

267 |

|

Fuel |

|

|

Additives …………………………………. |

365 |

|

Bleeding the system …………………. |

322 |

|

Diesel …………………………………….. |

364 |

|

Gauge …………………………………….. |

111 |

|

Important safety notes ……………… |

216 |

|

Refuelling ………………………………… |

216 |

|

Fuel consumption |

|

|

Driving style …………………………….. |

215 |

|

General notes ………………………….. |

215 |

|

Operating conditions ………………… |

215 |

|

Fuel filter with water separator |

|

|

Draining the prefilter …………………. |

321 |

|

Replacing the prefilter ………………. |

321 |

|

Fuel prefilter |

|

|

Replacing ………………………………… |

319 |

|

Fuel prefilter with water separator |

|

|

Important safety notes ……………… |

320 |

|

Fuses |

|

|

Closing the fuse box …………………. |

327 |

|

Important safety notes ……………… |

327 |

|

Layout …………………………………….. |

328 |

|

Opening the fuse box ………………… |

327 |

|

G |

|

|

Gauge |

|

|

AdBlue® ………………………………….. |

111 |

|

Fuel ………………………………………… |

111 |

|

Gearshift |

|

|

see Telligent gearshift |

|

|

General driving tips ……………………… |

208 |

|

Generator is not charging battery |

|

|

(display message) |

|

|

Yellow event window ………………… |

137 |

|

Genuine Mercedes-Benz parts ……….. |

32 |

|

Getting into and out of the vehicle |

|

|

Overview …………………………………… |

60 |

|

Grey event window |

|

|

Clutch heavily loaded ………………… |

130 |

|

Folding out the clutch pedal ………. |

130 |

|

Manual regeneration not possible |

|

|

(diesel particle filter) …………………. |

129 |

|

Refill washer fluid reservoir ……….. |

130 |

|

Regeneration disabled (diesel par- |

|

|

ticle filter) ……………………………….. |

129 |

|

Gross vehicle weight |

|

|

Vehicle identification plate ………… |

356 |

|

H |

|

|

Hazard warning lamps |

|

|

Switching on/off ………………………… |

76 |

|

Headlamp cleaning system |

|

|

Operation ………………………………….. |

89 |

|

Headlamp flasher ………………………….. |

75 |

|

Headlamp range control |

|

|

Adjusting ………………………………….. |

75 |

|

Headlamps |

|

|

Replacing bulbs …………………………. |

82 |

|

Heating |

|

|

Windscreen heating ……………………. |

90 |

|

Heating system |

|

|

Climate control ………………………….. |

99 |

|

High-pressure cleaning ………………… |

288 |

|

Hydraulic clutch mechanism sys- |

|

|

tem |

|

|

Brake fluid ………………………………. |

361 |

|

Hydraulic clutch operation system |

|

|

Checking the fluid level and top- |

|

|

ping up ……………………………………. |

295 |

|

Important safety notes ……………… |

294 |

|

Hydraulic connections |

|

|

Controlling, working hydraulics |

|

|

circuit I …………………………………… |

244 |

|

Power hydraulics ……………………… |

233 |

|

Working hydraulics …………………… |

230 |

|

Hydraulic fluid |

|

|

Checking the oil level (working |

|

|

hydraulics) ………………………………. |

298 |

|

Checking the oil level of the steer- |

|

|

ing …………………………………………. |

297 |

|

Environmentally-compatible |

|

|

hydraulic fluids ………………………… |

364 |

|

General notes ………………………….. |

363 |

|

Topping up (power hydraulics) ……. |

299 |

|

Topping up (working hydraul- |

|

|

ics) …………………………………………. |

298 |

|

Hydraulic fluids |

|

|

Synthetic ester ………………………… |

364 |

|

Hydraulic system |

|

|

«Settings», «Limits» menu win- |

|

|

dows ………………………………………. |

240 |

|

Activating/deactivating …………….. |

230 |

|

Buttons overview, vehicles with |

|

|

gear pump ………………………………. |

229 |

|

Buttons overview, vehicles with |

|

|

positioning pump ……………………… |

229 |

|

Changing the installation position |

|

|

of the control lever and controls …… |

95 |

|

Continuous consumers ……………… |

252 |

|

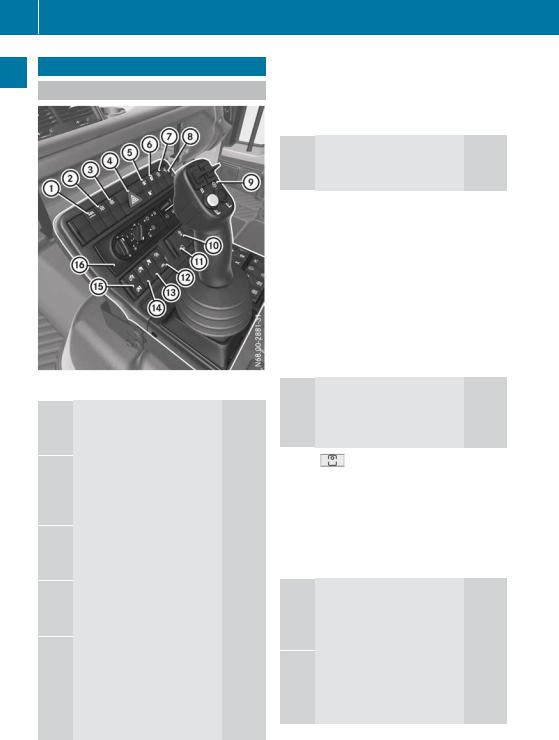

Control lever overview ………………. |

228 |

|

Controlling hydraulic connec- |

|

|

tions ………………………………………. |

244 |

|

Displaying the operating hours …… |

125 |

|

Float positions …………………………. |

246 |

|

Flow rate …………………………………. |

374 |

|

Flow rates, vehicles with a gear |

|

|

pump ……………………………………… |

374 |

|

Flow rates, vehicles with a posi- |

|

|

tioning pump ……………………………. |

374 |

|

Front working hydraulics circuit II, |

|

|

activating/deactivating, vehicles |

|

|

with positioning pump ………………. |

256 |

|

Hydraulic connections ………………. |

230 |

|

Hydraulic connections, types ……… |

373 |

|

Hydraulics input window ……………. |

237 |

|

Hydraulics menu window …………… |

235 |

|

Important safety notes ……………… |

228 |

|

Load profile 1 or load profile 2 |

|

|

function ………………………………….. |

239 |

|

Lowering restrictor …………………… |

245 |

|

Menus and input windows in the |

|

|

on-board computer …………………… |

234 |

|

Menus, brief instructions for the |

|

|

control lever ……………………………. |

235 |

|

Menus, brief instructions, buttons |

|

|

on the steering wheel ……………….. |

234 |

|

Index 13 |

|

|

Menus, general notes ……………….. |

234 |

|

Overview …………………………………. |

228 |

|

Overview of controls …………………. |

228 |

|

Power hydraulics circuit III/IV ……. |

258 |

|

Problems connecting hydraulic |

|

|

lines to working hydraulics cir- |

|

|

cuit II ……………………………………… |

233 |

|

Schematic diagram of power |

|

|

hydraulics ……………………………….. |

372 |

|

Schematic diagram of working |

|

|

hydraulics ……………………………….. |

370 |

|

Settings menu window ……………… |

240 |

|

Settings, automatic menu win- |

|

|

dows ………………………………………. |

242 |

|

Settings, back menu windows ……. |

243 |

|

Settings, function button menu |

|

|

windows …………………………………. |

241 |

|

Settings, resetting menu win- |

|

|

dows ………………………………………. |

243 |

|

Settings, save menu windows …….. |

242 |

|

Side and rear working hydraulics |

|

|

circuit II, activating/deactivating, |

|

|

vehicles with positioning pump …… |

257 |

|

Snow plough load relief …………….. |

248 |

|

Types ……………………………………… |

228 |

|

Working functions menu window … |

236 |

|

Working functions menu window, |

|

|

control lever operation ……………… |

237 |

|

Working functions menu window, |

|

|

operation using the buttons on the |

|

|

steering wheel …………………………. |

236 |

|

Working hydraulics circuit I ………… |

244 |

|

Working hydraulics circuit II, vehi- |

|

|

cles with gear pump, activating/ |

|

|

deactivating …………………………….. |

253 |

|

Hydrostatic drive system |

|

|

Activating ………………………………… |

199 |

|

Activating/deactivating standby |

|

|

mode, vehicles with Telligent® |

|

|

automatic gearshift …………………… |

201 |

|

Checking oil level ……………………… |

299 |

|

Constant working speed ……………. |

263 |

|

Deactivating …………………………….. |

200 |

|

Display message, red event win- |

|

|

dow ………………………………………… |

144 |

|

Displaying the operating hours …… |

125 |

|

Driving ……………………………………. |

201 |

|

Driving with the control lever ……… |

207 |

14 Index

|

Driving with the cruise control |

|

|

lever ……………………………………….. |

205 |

|

Driving, driving mode ………………… |

202 |

|

Driving, handling characteristics …. |

201 |

|

Driving, work mode …………………… |

202 |

|

General notes ………………………….. |

198 |

|

Work limiter …………………………….. |

204 |

|

Working mode cruise control ……… |

203 |

|

Working mode cruise control with |

|

|

work limiter …………………………….. |

203 |

|

Working speeds ……………………….. |

199 |

|

Hydrostatic unit faulty. Please |

|

|

apply brakes! (Display message) |

|

|

Red event window ……………………. |

144 |

|

I |

|

|

Identification plate |

|

|

Compressed-air reservoir ………….. |

380 |

|

Vehicle ……………………………………. |

356 |

|

Idling speed |

|

|

Engine speed setting ………………… |

263 |

|

Ignition lock |

|

|

Key positions …………………………… |

159 |

|

Immobiliser |

|

|

Activating ………………………………….. |

60 |

|

Deactivating ………………………………. |

59 |

|

Notes ……………………………………….. |

59 |

|

Implied warranty …………………………… |

27 |

|

Increased brake force and pedal |

|

|

travel (display message) |

|

|

Red event window ……………………. |

142 |

|

Insect protection on the radiator …… |

32 |

|

Instrument cluster |

|

|

AdBlue® ………………………………….. |

111 |

|

Displays ……………………………………. |

38 |

|

Fuel gauge ………………………………. |

111 |

|

Important safety notes ……………… |

110 |

|

Odometer ……………………………….. |

112 |

|

Rev counter …………………………….. |

110 |

|

Time and outside temperature ……. |

112 |

|

Warning and indicator lamps ……….. |

39 |

|

Instrument lighting |

|

|

Setting (on-board computer) ………. |

126 |

|

Interior lamp |

|

|

Replacing bulbs …………………………. |

88 |

|

Interior lighting |

|

|

Reading lamp …………………………….. |

76 |

|

Switching on/off ………………………… |

76 |

|

J |

|

|

Jack |

|

|

Pump lever ………………………………. |

313 |

|

Vehicle tool kit …………………………. |

312 |

|

Jump-start |

|

|

Socket ……………………………………… |

93 |

|

Jump-starting |

|

|

Important safety notes ……………… |

331 |

|

Jump lead ………………………………… |

332 |

|

Jump-starting socket …………………. |

332 |

|

Socket ……………………………………… |

93 |

|

Jump-starting socket |

|

|

Jump-starting …………………………… |

332 |

|

K |

|

|

Key |

|

|

Replacement key ……………………….. |

56 |

|

Key positions |

|

|

Ignition lock …………………………….. |

159 |

|

L |

|

|

Language |

|

|

Setting (on-board computer) ………. |

127 |

|

Licence plate lamp |

|

|

Replacing bulbs …………………………. |

85 |

|

Light |

|

|

Working area lamp ……………………… |

77 |

|

Light switch |

|

|

Important safety notes ……………….. |

74 |

|

Lighting system …………………………. |

74 |

|

Overview …………………………………… |

74 |

|

Light-alloy wheels |

|

|

Cleaning ………………………………….. |

289 |

|

Lighting system |

|

|

Auxiliary headlamps ……………………. |

77 |

|

Combination switch ……………………. |

75 |

|

Driving abroad …………………………… |

73 |

|

Exterior lighting control ………………. |

77 |

|

Hazard warning lamps ………………… |

76 |

|

Headlamp range control ……………… |

75 |

|

Interior lighting ………………………….. |

76 |

|

Light switch ………………………………. |

74 |

|

Notes on changing bulbs …………….. |

79 |

|

Overview of bulbs ………………………. |

81 |

|

Index 15 |

||||

|

Replacing bulbs |

82 |

|||

|

M |

||||

|

Rotating beacons |

79 |

|||

|

Main-beam headlamps |

||||

|

Strobe lights |

79 |

82 |

||

|

Replacing bulbs |

||||

|

Working-area lamps |

77 |

|||

|

Switching on/off |

75 |

|||

|

Lights |

||||

|

Combination switch |

75 |

Maintenance |

||

|

Batteries |

306 |

|||

|

Daytime driving lights |

74 |

|||

|

Checking anti-corrosion protec- |

||||

|

Dipped-beam headlamps |

74 |

|||

|

tion |

305 |

|||

|

Driving abroad |

73 |

|||

|

Checking oil level, Hydrostatic |

||||

|

Foglamps and rear foglamps |

74 |

|||

|

drive system) |

299 |

|||

|

Hazard warning lamps |

76 |

|||

|

Checking the engine oil level |

297 |

|||

|

Headlamp range control |

75 |

|||

|

Checking the oil level of the power |

||||

|

Limit speed (display message) |

299 |

|||

|

Yellow event window |

131 |

hydraulics ……………………………….. |

||

|

Checking the oil level of the steer- |

||||

|

Limiter |

297 |

|||

|

Deactivating |

193 |

ing and topping up oil ……………….. |

||

|

Checking the oil level of the work- |

||||

|

Load-sensing connections, vehi- |

||||

|

cles with positioning pump |

ing hydraulics ………………………….. |

298 |

||

|

Connecting attached equipment |

Checking the vehicle assemblies |

|||

|

for leaks |

305 |

|||

|

with load sensing connections |

232 |

|||

|

Cleaning the active charcoal filter |

303 |

|||

|

Overview of connections |

231 |

|||

|

Cleaning the air filter |

304 |

|||

|

Working hydraulics |

231 |

|||

|

Cleaning the fine particle filter |

303 |

|||

|

Loads |

||||

|

Ballast weights |

262 |

Cleaning the radiator ………………… |

301 |

|

|

Cleaning the release valve on the |

||||

|

Locking (doors) |

304 |

|||

|

From inside (central locking but- |

air intake duct ………………………….. |

|||

|

Coolant level |

293 |

|||

|

ton) |

57 |

|||

|

Displaying maintenance due date |

||||

|

Locking system |

123 |

|||

|

Key |

56 |

(on-board computer) …………………. |

||

|

Draining compressed-air reser- |

||||

|

Locking/unlocking the doors |

304 |

|||

|

Mowing door, inside |

58 |

voir circuit 1 …………………………….. |

||

|

Draining compressed-air reser- |

||||

|

Mowing door, outside |

58 |

|||

|

voir circuit 2 |

304 |

|||

|

Normal door, from inside with but- |

||||

|

Draining compressed-air reser- |

||||

|

tons |

57 |

|||

|

voir for auxiliary consumers |

304 |

|||

|

Normal door, from inside with |

||||

|

Draining compressed-air reser- |

||||

|

release lever |

57 |

|||

|

voir for tyre pressure control sys- |

||||

|

Normal door, from outside with |

||||

|

tem |

304 |

|||

|

key |

56 |

|||

|

Draining compressed-air reser- |

||||

|

Normal door, from outside with |

||||

|

voir regeneration |

304 |

|||

|

remote control |

57 |

|||

|

Draining the compressed-air |

||||

|

Normal door, inside |

57 |

|||

|

brake system |

304 |

|||

|

Normal door, outside |

56 |

|||

|

Draining the tyre pressure control |

||||

|

Lowering restrictor |

304 |

|||

|

Working hydraulics circuit I |

245 |

system ……………………………………. |

||

|

Front PTO shaft |

299 |

|||

|

Hydraulic clutch operation sys- |

||||

|

tem ………………………………………… |

294 |

|||

|

Notes ……………………………………… |

291 |

16 Index

|

Replacing the wiper blades ………… |

300 |

|

Torque converter clutch …………….. |

296 |

|

Windscreen washer system ……….. |

296 |

|

Manoeuvring/tow-starting and |

|

|

towing away |

|

|

Notes ……………………………………… |

333 |

|

Maximum permissible axle loads |

|

|

Vehicle identification plate ………… |

356 |

|

Maximum permissible gross vehi- |

|

|

cle weight |

|

|

Vehicle identification plate ………… |

356 |

|

Menus |

|

|

On-board computer, hydraulics ….. |

234 |

|

On-board computer, overview …….. |

117 |

|

Minimum tyre tread depth …………… |

338 |

|

Mirror arm |

|

|

Adjusting ………………………………….. |

72 |

|

Mirror heating |

|

|

Exterior mirror …………………………… |

72 |

|

Mirrors |

|

|

Additional mirror ………………………… |

72 |

|

Adjusting the exterior mirrors |

|

|

when using dual-mode steering ……. |

72 |

|

Adjusting the mirror arm ……………… |

72 |

|

Mixed air operation |

|

|

Switching on/off ……………………… |

100 |

|

Mobile phone |

|

|

External pairing ………………………… |

155 |

|

Important safety notes ……………….. |

96 |

|

Operating (on-board computer) ….. |

121 |

|

Pairing ……………………………………. |

154 |

|

Mowing door washer system |

|

|

Operation ………………………………….. |

90 |

|

Mowing door windscreen wiper |

|

|

Switching on/off ………………………… |

89 |

|

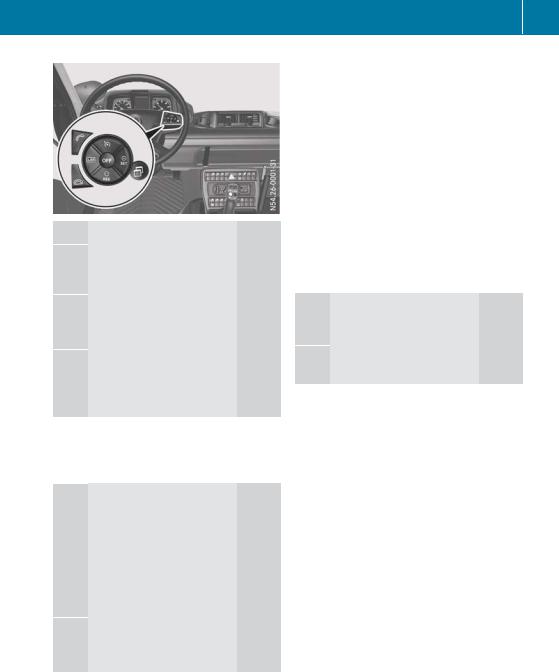

Multifunction lever |

|

|

Overview …………………………………… |

45 |

|

Multifunction steering wheel |

|

|

Adjusting ………………………………….. |

70 |

|

Dual-mode steering ……………………. |

70 |

|

Overview …………………………………… |

42 |

|

O |

|

|

Occupant safety |

|

|

Children in the vehicle ………………… |

51 |

|

Important safety notes ……………….. |

48 |

|

Pets in the vehicle ……………………… |

53 |

|

Restraint system introduction ………. |

48 |

|

Seat belt …………………………………… |

48 |

|

Odometer |

|

|

Trip meter ……………………………….. |

112 |

|

Off-road driving |

|

|

Check list after driving ………………. |

212 |

|

Checklist before driving off-road …. |

210 |

|

Driving downhill ……………………….. |

211 |

|

Driving on sand ………………………… |

212 |

|

Fording …………………………………… |

212 |

|

Oil |

|

|

Topping up (steering system) ……… |

297 |

|

see Engine oil |

|

|

Oil change …………………………………… |

361 |

|

Oil level |

|

|

Checking (power hydraulics) ………. |

299 |

|

Checking (steering system) ……….. |

297 |

|

Checking (working hydraulics) ……. |

298 |

|

On-board computer |

|

|

Activating backup drive mode |

|

|

(transmission shift system) ………… |

120 |

|

Alarm ……………………………………… |

120 |

|

Areas in the display ………………….. |

116 |

|

Audio and communications menu .. |

120 |

|

Axles menu window ………………….. |

123 |

|

Calling up the diagnostic data ……. |

125 |

|

Calling up/resetting trip com- |

|

|

puter ………………………………………. |

119 |

|

Calling up/resetting trip data …….. |

119 |

|

Checking driving time ……………….. |

119 |

|

Checking the coolant tempera- |

|

|

ture ………………………………………… |

125 |

|

Checking the engine operating |

|

|

hours ……………………………………… |

125 |

|

Checking the oil level ………………… |

125 |

|

Checking the range …………………… |

119 |

|

Checking the reservoir pressure …. |

124 |

|

Checking the rest period …………… |

119 |

|

Controls ………………………………….. |

115 |

|

Displaying events ……………………… |

125 |

|

Displaying maintenance due date .. |

123 |

|

Displaying the operating hours …… |

125 |

|

Displaying trailer/semitrailer |

|

|

data ……………………………………….. |

123 |

|

Displaying vehicle speed ……………. |

119 |

|

Driving mode menu …………………… |

119 |

|

Event window (display messages) .. |

128 |

|

Hydraulics menu window …………… |

123 |

|

Hydraulics, menus and input win- |

|

|

dows ………………………………………. |

234 |

|

Layout …………………………………….. |

115 |

|

Menus at a glance ……………………. |

117 |

|

Monitoring info ………………………… |

124 |

|

Notes on messages ………………….. |

128 |

|

Operating the audio equipment ….. |

122 |

|

Operating the telephone ……………. |

121 |

|

Operation and maintenance |

|

|

menu ……………………………………… |

123 |

|

Outside temperature display ………. |

118 |

|

Overview of warning and indicator |

|

|

lamps ……………………………………… |

144 |

|

Red warning/ indicator lamp ……… |

146 |

|

Setting instrument lighting ………… |

126 |

|

Setting the display language ………. |

127 |

|

Setting the engine oil grade ……….. |

127 |

|

Setting the engine oil viscosity …… |

127 |

|

Setting the rear axle oil grade …….. |

128 |

|

Setting the transmission oil grade .. |

127 |

|

Setting the unit of measurement … |

126 |

|

Setting the units ………………………. |

126 |

|

Settings menu …………………………. |

126 |

|

Showing the power hydraulics oil |

|

|

level ……………………………………….. |

125 |

|

Time ……………………………………….. |

118 |

|

Total distance recorder ……………… |

118 |

|

Trip data menu …………………………. |

118 |

|

Trip meter ……………………………….. |

118 |

|

Tyres menu window ………………….. |

123 |

|

Yellow warning/ indicator lamp ….. |

146 |

|

Opening/closing |

|

|

Rear window ……………………………… |

61 |

|

Operating and road safety (tyres) |

|

|

General notes ………………………….. |

338 |

|

Tyres ………………………………………. |

338 |

|

Operating hours |

|

|

Checking (on-board computer) …… |

125 |

|

Front PTO shaft ………………………… |

125 |

|

Hydraulic system ……………………… |

125 |

|

Hydrostatic drive system …………… |

125 |

|

Operating Instructions |

|

|

Before the first journey ……………….. |

27 |

|

General notes ……………………………. |

27 |

|

Implied warranty ………………………… |

27 |

|

Vehicle equipment ……………………… |

27 |

|

Operating lever |

|

|

Telligent® automatic gearshift ……. |

176 |

|

Index 17 |

|

|

Telligent® gearshift …………………… |

170 |

|

Operating safety |

|

|

Implied warranty ………………………… |

27 |

|

Operating safety and registration |

|

|

Attachments/add-on equipment ….. |

31 |

|

BlueTec® exhaust gas aftertreat- |

|

|

ment ………………………………………… |

30 |

|

Changes in engine performance …… |

30 |

|

Installations and conversions ……….. |

31 |

|

Notes on body/equipment |

|

|

mounting directives ……………………. |

31 |

|

Notes on fitting equipment ………….. |

32 |

|

Operating safety and vehicle |

|

|

approval |

|

|

Correct use ……………………………….. |

27 |

|

Declaration of conformity ……………. |

29 |

|

Notes on operating the vehicle …….. |

29 |

|

Qualified specialist workshops …….. |

30 |

|

Registering your vehicle ………………. |

30 |

|

Operating system |

|

|

see On-board computer |

|

|

Outside temperature display |

|

|

Instrument cluster ……………………. |

112 |

|

On-board computer ………………….. |

118 |

|

Overhead control panel |

|

|

Overview …………………………………… |

37 |

|

Overview of hydraulic system con- |

|

|

trols ……………………………………………. |

228 |

|

P |

|

|

Pairing ………………………………………… |

154 |

|

Parking |

|

|

Vehicle ……………………………………. |

162 |

|

Parking brake |

|

|

Applying ………………………………….. |

166 |

|

Applying (display message) ………… |

142 |

|

Four-wheel parking brake ………….. |

166 |

|

Releasing ………………………………… |

166 |

|

Testing ……………………………………. |

166 |

|

Parking up the vehicle …………………. |

310 |

|

Perimeter lamp |

|

|

Replacing bulbs …………………………. |

85 |

|

Perimeter/side marker lamp |

|

|

Replacing bulbs …………………………. |

85 |

|

Pets in the vehicle …………………………. |

53 |

|

Platform dropside |

|

|

Important safety notes ……………… |

274 |

18 Index

|

Platform dropsides |

|

|

Access steps …………………………… |

276 |

|

Letting the tailgate swing freely ….. |

275 |

|

Opening ………………………………….. |

275 |

|

Opening the tailgate …………………. |

275 |

|

Rear platform dropside ……………… |

275 |

|

Removing ………………………………… |

275 |

|

Removing the post ……………………. |

276 |

|

Removing the tailgate ……………….. |

276 |

|

Tipper platform ………………………… |

274 |

|

Power hydraulics |

|

|

Checking the oil level ………………… |

299 |

|

Hydraulic connections ………………. |

233 |

|

Important safety notes ……………… |

299 |

|

Schematic diagram …………………… |

372 |

|

Showing the oil level (on-board |

|

|

computer) ……………………………….. |

125 |

|

Topping up the hydraulic fluid …….. |

299 |

|

Power hydraulics circuit III/IV |

|

|

Activating/deactivating …………….. |

258 |

|

General notes ………………………….. |

258 |

|

Power steering |

|

|

see Steering |

|

|

Power supply |

|

|

see Voltage supply |

|

|

Power take-off |

|

|

Pulling away in equipment driving |

|

|

mode ……………………………………… |

266 |

|

Shifting gears in equipment driv- |

|

|

ing mode …………………………………. |

266 |

|

Stopping in equipment operating |

|

|

mode ……………………………………… |

266 |

|

Power take-offs |

|

|

Engine-driven power take-off ……… |

265 |

|

General notes ………………………….. |

264 |

|

Transmission-driven power take- |

|

|

off ………………………………………….. |

265 |

|

Power windows |

|

|

see Side windows |

|

|

Preparing for a journey |

|

|

Checking emergency equipment/ |

|

|

first-aid kit ………………………………. |

158 |

|

Checking the vehicle lighting, turn |

|

|

signals and brake lamps ……………. |

158 |

|

Fuel/AdBlue® level …………………… |

159 |

|

Visual check of the vehicle exte- |

|

|

rior …………………………………………. |

158 |

|

Protection of the environment |

|

|

General notes ……………………………. |

28 |

|

Pulling away |

|

|

Vehicle ……………………………………. |

162 |

|

Pump lever |

|

|

Assembling/disassembling ……….. |

313 |

|

Cab tilting pump ………………………. |

313 |

|

Jack ……………………………………….. |

313 |

|

Vehicle tool kit, storing ……………… |

312 |

|

Wheel wrench ………………………….. |

313 |

|

Q |

|

|

Qualified specialist workshop ……….. |

30 |

|

Quick change system for the tipper |

|

|

platform |

|

|

Installing …………………………………. |

284 |

|

Removing ………………………………… |

282 |

|

R |

|

|

Radiator cover ………………………………. |

32 |

|

Radio |

|

|

Adjusting the volume ………………… |

122 |

|

Changing the audio source or |

|

|

title/station …………………………….. |

122 |

|

Radio-based vehicle components |

|

|

Declaration of conformity ……………. |

29 |

|

Range |

|

|

Checking (on-board computer) …… |

119 |

|

Rear axle |

|